Our clients can avail from us premium quality . We use superior quality base material to ensure durability and reliability of Thermoplastic Blanket Adhesive.

Thermoplastic Blanket Adhesive

|

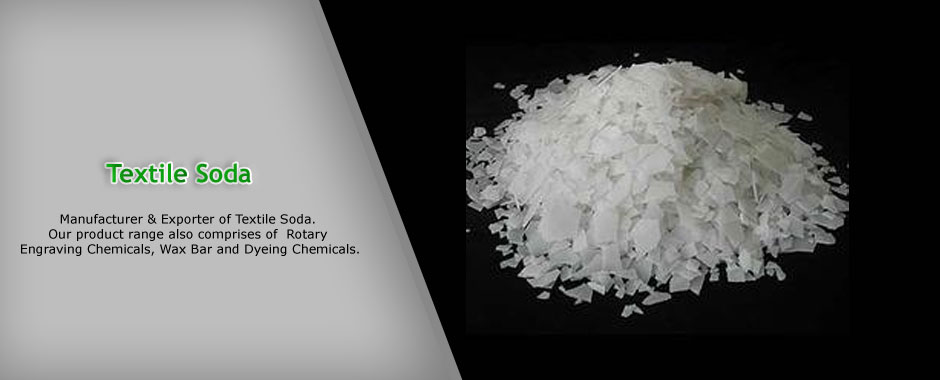

Our organization is a processor and supplier of a wide range of Thermoplastic Blanket Adhesives. These adhesives are highly demanded by our clients and can be availed in varied packaging options. Further, these are non-toxic and do not contain organic components.

Following are the properties of these products:

1) It does not attack printing surface of machine belts.

2) It is free from aromatic hydrocarbon and other harmful chemicals. 3) It does not react with printing auxiliaries any emulsion agents. Technical Data :-

1) Appearance : Clear light Tinch Oily Liquid.

2) Solid Content : Approx 25 to 30 % on dry basis. 3) Viscosity : 400 - 800 Cps. Features:

1)Klebstoff adhesive is thermoplastic permanent adhesive for textile printing. It forms a solid film on Blanket..

2) It is Soluble in Ethyl Acetate, Acetone and other similar solvent. Acetone affects Rubber on Blanket. So we recommend - use of Ethyl Acetate. 3) Klebstoff LT at 28 o C to 30 o C get activated and get tackiness. 4) Klebstoff MT at 45 o C to 50 o C get activated and get tackiness. 5) Klebstoff HT at 75 o C to 80 o C get activated and get tackiness. 6)The tackiness get disappears when temperature sinks beyond it's activity range Properties :-

1) Klebstoff adhesive does not attack printing surface of machine belts. It's free from aromatic hydrocarbon and other harmful chemicals..

2) Klebstoff adhesive is non toxic and free from the organic components. 3) It has an extensive durability and strength. 4)It does not react with printing auxiliaries any emulsion agents. Sequence of Application :-

1)Before applying Klebstoff adhesive, clean the blanket with degreaser, ethyl acetate/ Butyl Acetate/thinner/mix solvent thoroughly. Also clean guide rolls below blanket and remove duct particles, colors, fluff etc. with ethyl acetate or butyl acetate. Take care to clean all parts of printing machine coming in contact with blanket.

2)After Washing and cleaning of Blanket keep it for drying as per your equipment once it get dried then it is ready for coating. 3) Firstly coat the Blanket with Klebstoff HT for even surface as base coat uniformly. Now let the Blanket rotate for 3 to 4 hrs for drying. Now before applying the second coat check the temperature of department and then decide to use Klebstoff LT or Klebstoff MT or mixture of both. 4)This mixture depends upon the season/fabric to be printed etc. Mixture is coated one again on Blanket. Rotate Blanket twice or thrice. Now leave Blanket drying for blanket 4 - 6 hrs. 5)Approximately total 6 kgs.material for coating is recommended approximately for 40Sq mtr area. It means 150 gms of Klebstoff adhesive will be consumed per sq mtr for to get rich coating. |